Policy

Delivering High-Quality Eisai Products to More Patients Around the World

Eisai recognizes our social responsibility, as a pharmaceutical company, to ensure a stable supply of high-quality pharmaceutical products and their safe delivery to patients, as we are handling products which directly affect people's lives. Based upon our sense of responsibility and high ethical standard, we established the following General Policy on Product Quality to help us deliver high quality products around the world to those who need them.

Eisai General Policy on Product Quality

The quality of every single tablet, capsule and ampoule that we produce is integral to the life of the patients.

Materiality, Targets, Issues, Actions and Achievements

*You can scroll left and right

| Materiality | Targets | Issues | Actions | Achievements |

|---|---|---|---|---|

| Stable supply of products | Enhancement of stable operation and stable supply system | Dependence on specific countries for raw material procurement | Consider alternative suppliers |

|

| Establishment of stable supply structure in the event of an emergency |

Secure adequate inventory Secure alternative transportation routes |

|

||

| Establish sustainable and robust stable supply system |

|

|||

| Improve access to medicines |

|

|||

| Measures against counterfeit medicine |

|

|||

| Sustainability initiatives | Reduction of GHG emission toward realization of carbon neutrality, decarbonized society | Promotion of carbon neutrality initiatives based on environmental changes such as changes in regulations and advancement in technologies |

Each site promotes

|

|

| Promotion of socially and environmentally sustainable procurement in cooperation with business partners | Establishment of sustainable and stable procurement structure by promoting CSR (Corporate Social Responsibility) procurement |

|

Requested both domestic and global business partners for

|

A Global Structure to Ensure the Stable Supply of Medicines

With the aim of achieving more patient-oriented pharmaceutical production and distribution, Eisai is building systems not just for the production and supply of products, but also to ensure that production activities and product improvements are actively geared to meeting the demands of patients.

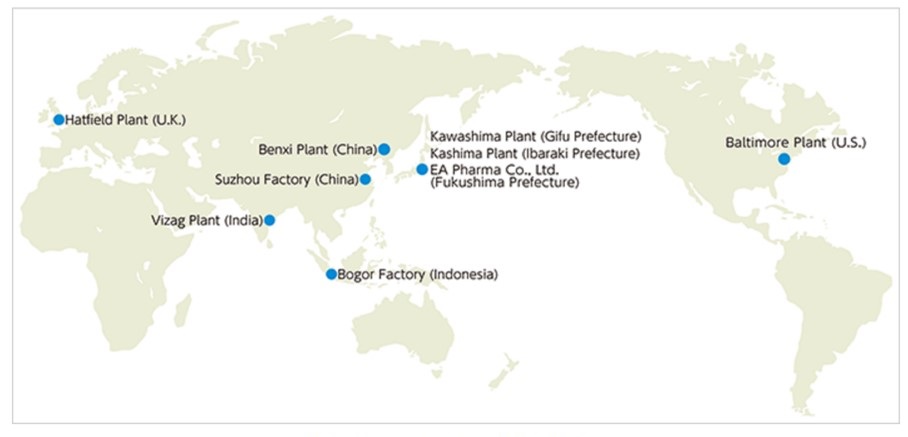

At present, Eisai has manufacturing facilities in Japan, the United States, the United Kingdom, China, India and Indonesia. Through global coordination and considerate response to local needs, these facilities are utilized in a flexible manner to provide a stable supply of high-quality products to anywhere in the world.

Initiatives

Sustainable Procurement

Eisai promotes socially and environmentally conscious business activities throughout the entire supply chain, and sustainable procurement is one of these activities. The purpose of sustainable procurement is to understand and improve the sustainability initiatives of business partners in areas such as human rights, labor, safety and health, environment, and ethics, through engagement. For details please visit Sustainable Procurement.

Carbon Neutrality

Eisai’s medium- to long-term target for reducing the GHG emissions that cause global warming: is switching 100% of our total electric power to renewable energy by fiscal 2030 and achieving carbon neutrality by fiscal 2040. Eisai is promoting activities according to the roadmap developed at all 9 manufacturing sites such as installation of energy saving equipment and solar power generation systems, shifting from fossil fuel to electricity to reduce CO2 emissions, and introduction of renewable energy.

Biomass-based plastic containers (polyethylene derived from sugarcane)

We have adopted biomass-based plastic containers for the packaging of the new fine granule formulation of our antiepileptic agent Fycompa® (generic name: perampanel), which was launched in July 2020. Containing more than 90% biomass polyethylene, this container has been certified by the Japan BioPlastics Association to be labelled as a biomass-based plastic product (the BiomassPla mark). Use of this packaging can reduce CO2 emissions by as much as 70% compared to conventional petroleum-derived polyethylene. We will continue our efforts to further reduce environmental impact by considering its use with other products. At the same time, we will implement other initiatives based on changes in conditions, including changes in Japan and international regulations and the development of innovative technologies, contributing to the creation of a sustainable society aimed at the realization of a carbon neutral, decarbonized society.

Next-generation Plants Targeting Automation and Remote Operation

Eisai is committed to building a sustainable, robust, and stable supply system to deliver medicines to patients in any environment. By converting our own manufacturing sites to automated, remotely controlled manufacturing and analysis operations, we aim to shift to a production system that, in the event of an emergency, is unaffected by restrictions on employee attendance.

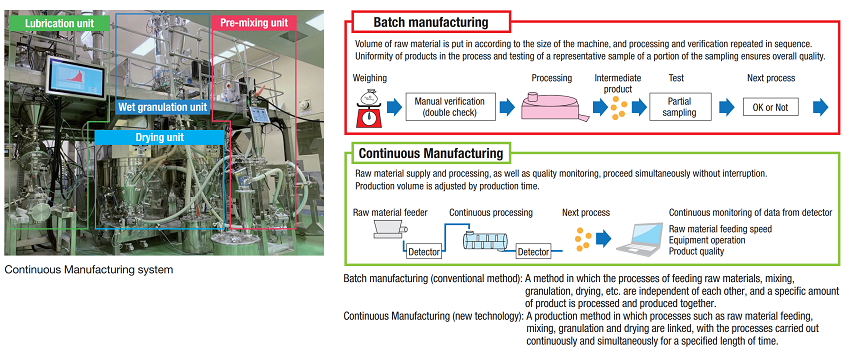

Continuous Manufacturing System for the Formulation Process

We applied a continuous manufacturing system to the anticancer agent Tazverik®, which was approved in Japan in June 2021, making Eisai the first company in Japan to put the system into practical use in commercial production. In continuous manufacturing, raw material input, mixing, granulation, drying, and other processes are linked to produce the final product while monitoring the quality of the manufacturing process in real time. This is an innovative medicine production technology that can adjust production volume according to operating hours, and reach high production efficiency while saving energy.

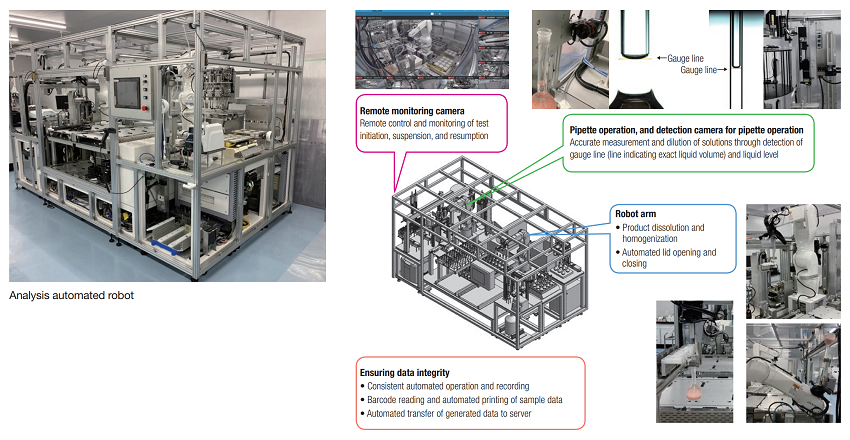

Automated Analysis Robot

In order to automate and remotely monitor the series of operations required when measuring ingredients and impurities in products, including complete dissolution and accurate dilution, Eisai developed an automated robot to analyze product quality of the anticancer agent Lenvima® (lenvatinib mesylate) in cooperation with outside manufacturers. The automated robot was introduced in March 2022, and it went into practical use in fiscal 2022. The introduction of this equipment improves testing capacity, including the ability to work unattended at night. In addition, consistent, automated operation and recording, digitalization, and automation of sample data management, and the automatic transfer of generated data to servers will contribute significantly to improving data integrity (completeness, consistency, and accuracy).

Activities to Improve Access to Medicines

The realization of affordable pricing is crucial for improving access to medicines, one of the aims of the Eisai Group. The Vizag Plant is one manufacturing plant that plays a central role in the achievement of affordable pricing (prices in consideration of income levels and health care systems of each country). This plant has obtained GMP* approval from Japan, the United States and India as a manufacturing plant for active pharmaceutical ingredients (APIs) and formulations as well as approval from European countries and South Korea as a manufacturing plant for APIs. In this manner, it has established a role as a production plant serving the entire world, including emerging countries.

-

*GMP: GMP stands for “Good Manufacturing Practice” and means the series of standards related to manufacturing controls and quality assurance for medicinal products

Eisai continues to supply DEC tablets (diethylcarbamazine citrate) free of charge to eliminate Lymphatic Filariasis

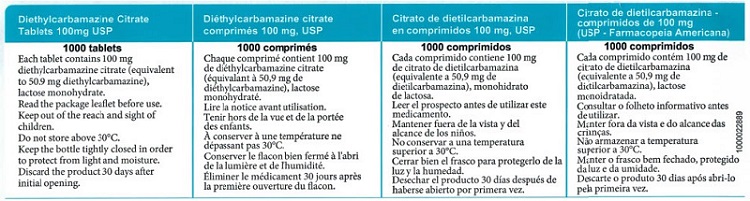

For the WHO DEC Provision Program, Eisai supplies DEC tablets, manufactured by its Vizag plant, free of charge since October 2013. The formulation of DEC tablets was developed by the Vizag plant. The packaging label on the bottle is written in four languages (English, French, Spanish, and Portuguese) to make people living in at-risk communities comfortable with taking the medicine. Furthermore, as one of the measures against counterfeiting, each label on a bottle has a unique identification number with a 2D barcode for tracking and tracing as Eisai products. In addition, a serial number is also printed on both the outer carton and pallet to prevent counterfeiting.

Initiatives for Lymphatic Filariasis

Provisions for Major Disasters and Pandemics

The Eisai Group has a business continuity plan (BCP) to enable a stable supply of products even in the event of a major disaster or other emergency situation. Under a Group-wide policy that encompasses the Eisai Network Companies, Eisai systematized and upgraded various functions and regional BCPs, and established a framework for making a globally consistent response.

In this BCP, Eisai stipulates plans and processes for the continuation of business activities related to production logistics, such as continuation of factory operations, minimizing of damages, and early recovery, while placing the highest priority on ensuring the safety of employees in anticipation of any and all emergencies. In addition, we secured an inventory of raw materials and products appropriately in order to provide a stable supply of our products even in the event of a situation that interferes with raw material procurement, production, or distribution. We are also undertaking initiatives for securing backup sites that enable alternate operations in times of emergency, primarily for specific products, especially those with a high degree of urgency and importance. Furthermore, to prepare for outages of commercial power sources, Eisai installed in-house power generators in all domestic and overseas plants to secure necessary electric power. We are promoting the building of a stronger and more flexible structure for ensuring stable supplies.