Policy and Basic Concept

Eisai has established the Eisai Network Companies (ENW) Safety & Health Policies based on the fundamental principle of undertaking corporate activities with respect for human dignity, and placing the highest priority on safety and health. The policies stipulate seven safety and health guidelines, and we prepare annual policies and plans in accordance with these guidelines. Sharing the fundamental principle among all employees, we carry out activities to secure safety and health with the aim of realizing a workplace which will not hurt or cause sickness to anyone.

Eisai Network Companies (ENW) Safety & Health Policies

Fundamental Safety & Health Policy

Eisai and its Group companies (hereafter ENW) place safety and health as a top priority and promote business operations respecting human life and dignity that support a work-life balance.

Safety & Health Guidelines

- ENW places safety and health as a top priority in all business operations and continuously pursues a policy of no accidents, injuries ordisasters.

- ENW prevents recurrence of occupational accidents and accidents by grasping their occurrence status based on the common standards of ENW, sharing information on causes, corrective measures, recurrence prevention measures, and other efforts, and leveraging them.

- ENW places safety and health as a top priority at all stages of corporate activities from research and development, production, distribution, sales to product usage and disposal.

- ENW constructs and operates a safety and health management system (including infection) and promotes this in all operations.

- ENW complies with all applicable laws, regulations and agreements concerning safety and health, and each Group company implements voluntary standards that exceed the minimum standards set forth in the applicable laws, regulations and agreements.

- ENW actively introduces advanced technology to be at the forefront of safety technology.

- ENW shares the fundamental safety and health policy, and implements educational training to strengthen specialties at each workplace progressively and continuously.

- ENW actively discloses information on policies, objectives, programs and results concerning safety and health.

May 30, 2025

Teruyuki Masaka

Vice President, General Affairs

Eisai Co., Ltd.

Targets, Issues and Actions

| Materiality | Goal | Issues | Action | Achievement (FY2023 Eisai Group) |

|---|---|---|---|---|

|

Preparing a suitable working environment and healthcare support to assist self-actualization Undertaking corporate activities with respect for human dignity and placing the highest priority on safety and health. |

Realizing a workplace which will not hurt or cause sickness to anyone

|

|

|

Number of work-related accidents: 62 Lost Time Injury Frequency Rate (LTIFR), more than 1 day* (per million hours of actual work) : 0.65 Number of work-related fatalities: 0 |

-

*Eisai Group Lost Time Injury Frequency Rate (per million hours of actual work) = Number of casualties resulting from occupational and traffic accidents (absence of 1 day or more) ÷ Total working hours × 1,000,000

Main efforts

Efforts toward "Zero-Sai (Zero occupational accidents)"

In addition to the preparation of operational manuals and the acquisition of skills and knowledge by employees, we will globally share and utilize information on the causes, countermeasures, and recurrence prevention measures regarding occupational accidents and incidents, and promote "Zero-Sai". We will also enhance health and safety education and training to enable employees to act based on the principle of protecting themselves by inheriting the know-how and past failures at each site and strive to eliminate unsafe conditions and unsafe behavior.

Efforts to prevent of the spread of COVID-19 infection

We will continue efforts to prevent the spread of COVID-19 infection, such as providing health and safety information and reforming the work environment in offices and workplaces according to the infection situation. In the event of an infected employee, we will work to prevent the spread of infection in accordance with the procedure manual and prevent clusters from occurring within the company.

Commitment to employees' mental and physical health

We will work to maintain and promote the physical and mental health of employees in cooperation with medical staff, by promoting the use of consultation services, etc., while giving due consideration to the wishes of employees. In addition, we will continue our efforts to correct long working hours and encourage employees to take paid leave, while preventing mental health problems by using the stress check system to ascertain the extent of stress. In particular, we will pay attention to maintaining the physical and mental health of employees due to changes in the environment, such as an increase in working from home due to the COVID-19 pandemic.

Management of chemical substances

We will strengthen the management of chemical substances based on risk assessment from the perspective of compliance with laws and regulations concerning the handling of chemical substances and the protection of workers.

Compliance with laws and regulationsIn compliance with laws and regulations to prevent occupational accidents and incidents, we will strive to eliminate unsafe conditions and unsafe behaviors in the workplace. At business sites that have an occupational health and safety management system (OHSAS), we will make effective use of such management system.

Structures and Systems

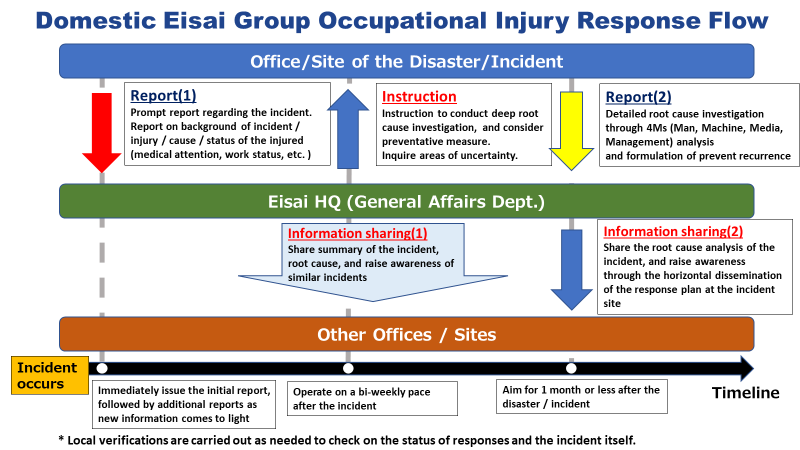

The response flow in the event of a workplace accident in Japan is shown below.

Initiatives

Under the Industrial Safety and Health Act, committees have been established at each of Eisai’s offices in Japan with 50 employees or more. In the committees, periodic discussions on occupational safety and health are held with labor union representatives. Furthermore, the company-wide Environment and Safety Committee has been established to eliminate operational accidents throughout the company and set annual plans to further improve the quality of activities and monitor the occurrence of operational accidents and injuries on a quarterly basis, confirm the results and issues of initiatives, and share globally and utilize the information to prevent a similar accidents from recurring in the future. For fiscal 2023, after analyzing and investigating past industrial accidents, it was determined that there were many accidents among employees with short and insufficient work experience, and this was set as a key theme.

Similarly, major research and production facilities of the Eisai Group both in and outside Japan have established occupational safety and health management systems and are undertaking relevant activities. These sites and facilities are striving to raise the level of occupational safety and health by appropriately operating their respective management systems and by voluntarily and continually going through the PDCA* cycle. At the Kawashima plant in Japan, employees with the work experience for less than a year are asked to submit honest feedback about inconveniences or risks they encounter in the workplace. Based on the results of these investigations, countermeasures are considered as necessary and reported at the monthly Environment and Safety Committee meetings. Furthermore, risk assessments are carried out not only on new facilities and buildings, but also on the handling of chemical substances based on amendment of the Industrial Safety and Health Act in May 2022. In cooperation with industrial physicians and health insurance associations, Eisai also engages in efforts to help its employees stay in good health and grow even healthier, both physically and mentally.

-

*A method for continually improving management operations by repeating the plan-do-check-act (PDCA) cycle.

Data

| Fiscal 2023 | |||

|---|---|---|---|

| Number of work-related accidents (lost time injuries, non-lost time injuries, traffic accidents) | Eisai Co., Ltd. | 8*4 | |

| Global*1 | 62*4 | ||

| Lost Time Injury Frequency Rate (LTIFR), more than 4 day*2 | Employee | Eisai Co., Ltd. | 0*4 |

| Lost Time Injury Frequency Rate (LTIFR), more than 1 day*3 | Employee | Global*1 | 0.65*4 |

| Number of work-related fatalities | Employee | Eisai Co., Ltd. | 0*4 |

| Employee | Global*1 | 0*4 |

-

*1Eisai Co., Ltd. and Group companies in and outside Japan

-

*2Eisai Co., Ltd. Lost Time Injury Frequency Rate = Number of casualties resulting from occupational and traffic accidents (absence of 4 day or more) ÷ Total working hours × 1,000,000

-

*3Eisai Group Lost Time Injury Frequency Rate = Number of casualties resulting from occupational and traffic accidents (absence of 1 day or more) ÷ Total working hours × 1,000,000

-

*4These figures cover employees, part-time workers, and temporary workers.