Prevention of Environmental Pollution

As a global healthcare company, the Eisai Group has established the ENW (Eisai Network Companies) Environmental Policy to guide its business activities with an emphasis on global environmental protection. One of the key commitments is to “4. Prevent environmental pollution by promoting proper management of chemical substances.” In line with this, we are globally developing business activities with careful consideration for the use of chemical substances, ensuring compliance with relevant laws and regulations and proper management.

With regard to PRTR (Pollutant Release and Transfer Register) substances and VOC (Volatile Organic Compounds), which may impact the environment, we are working to utilize alternative solvents and develop synthesis methods in the research phase to reduce the amounts of substances used, in order to prevent environmental pollution. We are also incorporating various means into our manufacturing processes to minimize their release into the atmosphere. In addition, to prevent global warming we are reducing emissions of fluorocarbons, including hydrochlorofluorocarbons (HCFCs) and chlorofluorocarbons (CFCs) that have ozone-depleting effects and strong greenhouse effects, and shifting to hydrofluorocarbons (HFCs) and non-fluorocarbons (NON).

Targets and Actions

Proper Management of PRTR Substances

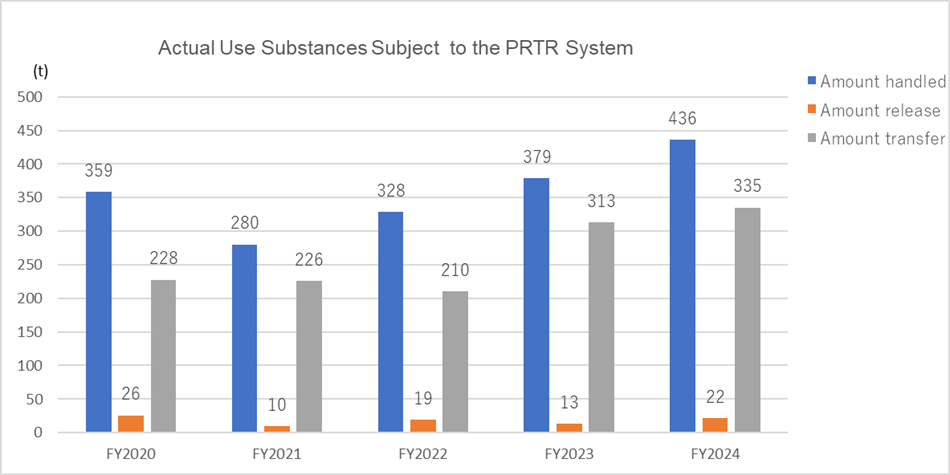

Chemical substances that are used in the research and development and production of pharmaceutical products include some substances subject to the PRTR system in various countries that could have an impact on the environment. The amount of these substances handled, released into the environment, and transferred as waste need to be understood and properly managed. The Eisai Group globally promotes proper management of PRTR substances. The Eisai Group in Japan also strives to reduce emissions of PRTR substances into the environment, and when the amount of PRTR substances used exceeds the designated limit, we promptly submit notifications to the relevant prefectures.

Volatile Organic Compounds (VOCs) Release Control

VOCs, such as ethyl acetate, acetone and methanol are highly volatile and turn into gas in the atmosphere, and as is the case with NOx discharged from production plants, cause the generation of photochemical oxidants. From the viewpoint of preventing air pollution, these substances need to be controlled to reduce their release into the atmosphere. The Eisai Group globally promotes the reduction of VOC emissions.

Management of Fluorocarbons

Fluorocarbons including hydrochlorofluorocarbons (HCFCs) and chlorofluorocarbons (CFCs) used in air conditioners and as refrigerants for refrigerators and freezers have ozone-depleting effects and strong greenhouse effects. The Eisai Group is promoting the reduction of fluorocarbon emissions and the transition to hydrofluorocarbons (HFCs) and non-fluorocarbons (NON) from the perspective of preventing global warming.

Structures and Systems

The Eisai Group has established an environmental management system to promote global activities and is working to strengthen activities to identify environmental risks and establish countermeasures in Japan and overseas.

Promotion Structure and Environmental Audit

https://www.eisai.com/sustainability/environment/management/structure/index.html

Initiatives

Proper Management of PRTR Substances

The Eisai Group in Japan uses its own reagent management system to monitor the use of reagents and strives to reduce emissions of PRTR substances into the environment. When the amount of PRTR substances used exceeds the specified amount, prompt notification is submitted to the relevant prefectures.

The amount of chemical substances used in the manufacturing process depends largely on the amount of pharmaceutical products. In the commercial production stage, it is not easy to change the manufacturing process because of the need to maintain the quality of the active pharmaceutical ingredient. For green sustainable chemistry*1, we aim to reduce our environmental impact from the R&D stage by reducing the use of chemical substances and developing synthesis methods using alternative solvents. When highly volatile PRTR substances are used, we strive to control their release into the atmosphere as much as possible and incorporate them into our manufacturing processes.

*1 Chemical technology that considers the environment and supports the sustainable development of society.

Volatile Organic Compounds (VOCs) Release Control

Our major plants and laboratories in Japan are working to reduce the use of VOCs and PRTR substances. We have also established equipment operation methods to minimize emissions from our manufacturing processes.

Management of Fluorocarbons

The Eisai Group in Japan is systematically eliminating and replacing equipment that uses chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFC) with equipment that uses hydrofluorocarbons (HFCs) or non-fluorocarbon refrigerants, which do not deplete the ozone layer. Because CFCs have a strong greenhouse effect, we regularly inspect our equipment to prevent leakage, and in the unlikely event of a leak, we promptly share information and take action to prevent recurrences. At the time of equipment disposal, we ensure that all fluorocarbons have been properly collected, destroyed, and disposed of, and obtains a disposal certificate from the contractors.

Data

Proper Management of PRTR Substances

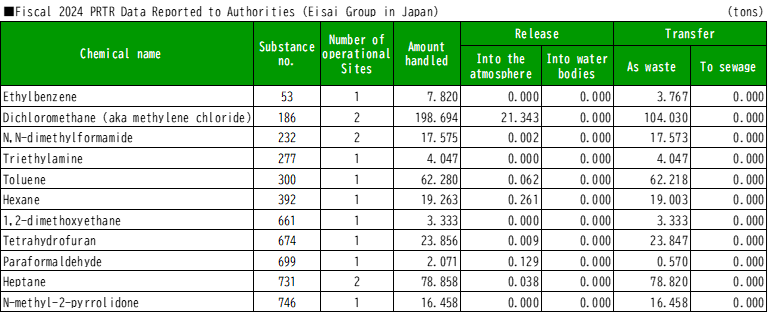

In FY2024, total amount of PRTR substances used by the Eisai Group in Japan was 436 tons, making a 15% increase from the previous fiscal year. This increase was primarily due to higher production volumes of anti-cancer drugs, and neurology drugs. Following the partial revision of “the Act on confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof” which came into effect in FY2023, a review of substances subject to PRTR was conducted. As a result, the amount of PRTR substances handled increased, and eleven substances were reported to the authorities, three substances more than in the previous fiscal year.

Volatile Organic Compounds (VOCs) Release Control

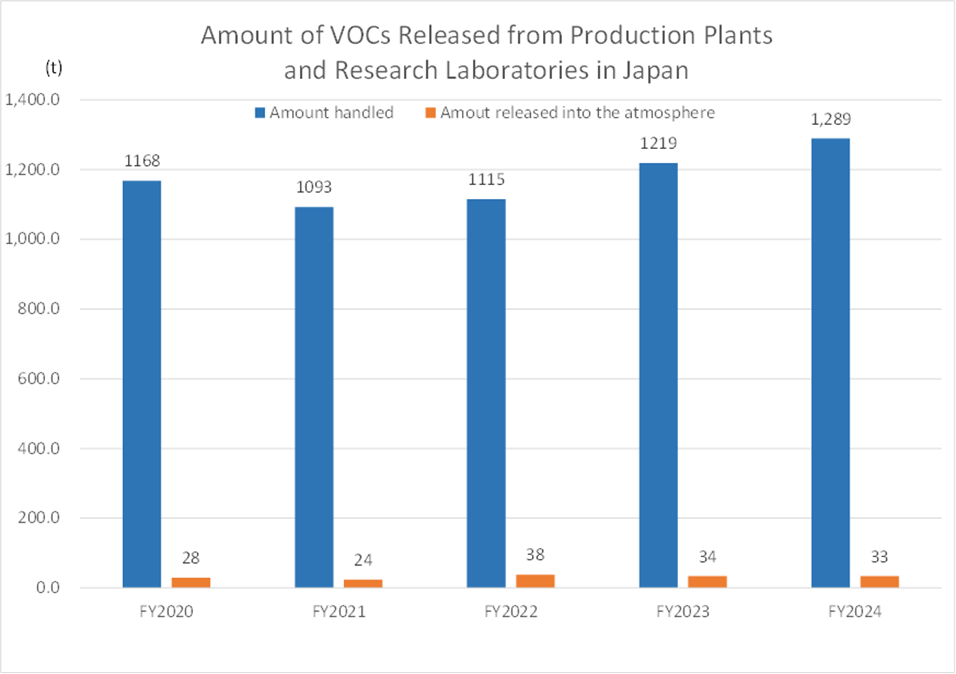

The figure below shows changes over time in the volume of 55 of the 100 major VOCs designated by the Ministry of the Environment, excluding PRTR substances, used and released into the atmosphere by Eisai Group’s plants and laboratories in Japan. In fiscal 2024, the Eisai Group in Japan used 1,289 tons of VOCs, a 5.7% increase from the previous year. However, due to measures implemented at plants and research laboratories, emissions into the atmosphere were kept at 33 tons (2.6% of the total amount of VOCs handled).

Management of Fluorocarbons

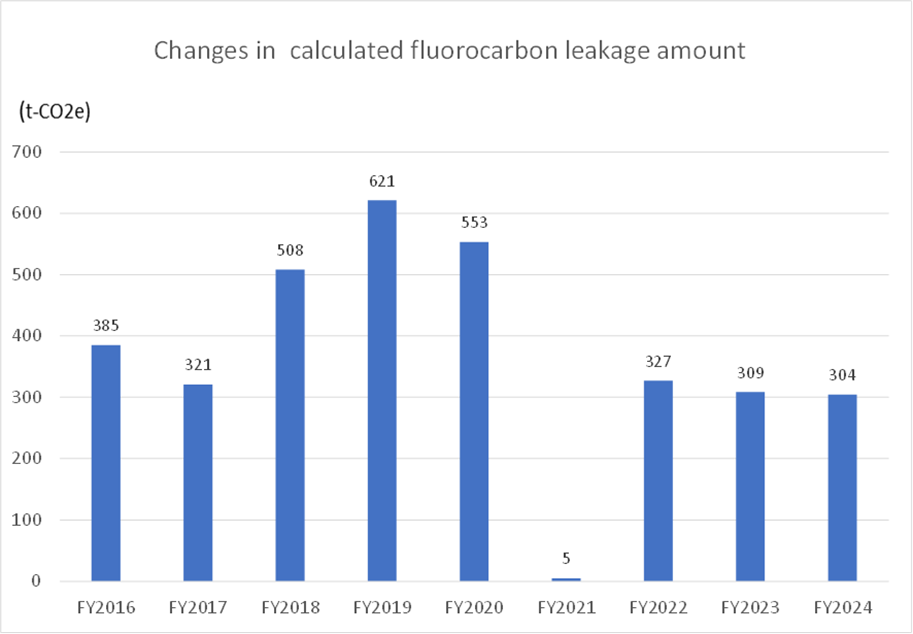

Based on the Act on Rational Use and Appropriate Management of Fluorocarbons, Eisai Group’s fluorocarbons in fiscal 2024 were 304 t-CO2. This is the ninth consecutive year since the Act took effect that our emissions have remained below the reporting threshold (i.e., 1,000 t-CO2) to the Ministry of Health, Labor and Welfare. We will continue to conduct regular inspections to prevent the release of fluorocarbons, which have strong greenhouse effect.

Eisai Co., Ltd. received an A rating for the fourth consecutive year in the fourth assessment survey on compliance with “Act on Rational Use and Appropriate Management of Fluorocarbons” conducted by the Japan Refrigerants and Environment Conservation Organization (JRECO).

(https://www.jreco.or.jp/data/2024_Kakuduke_Ranking_0206.pdf)

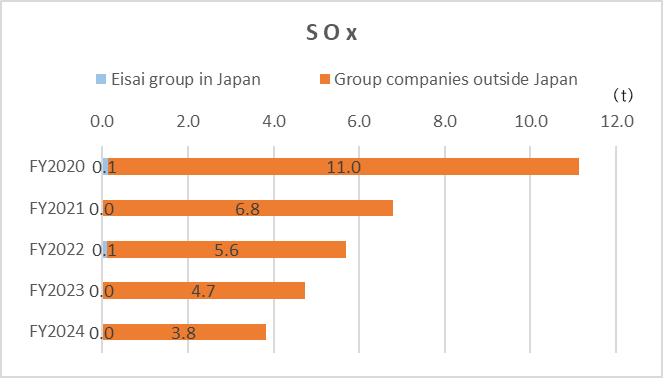

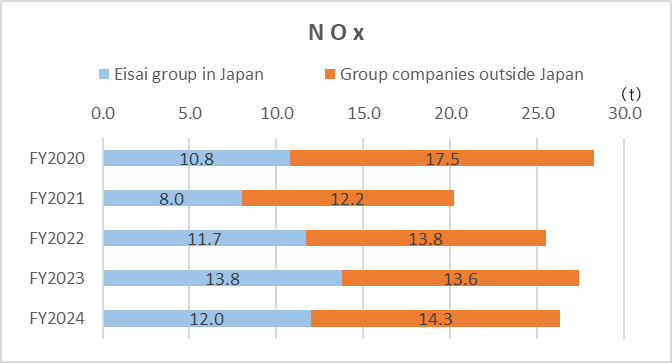

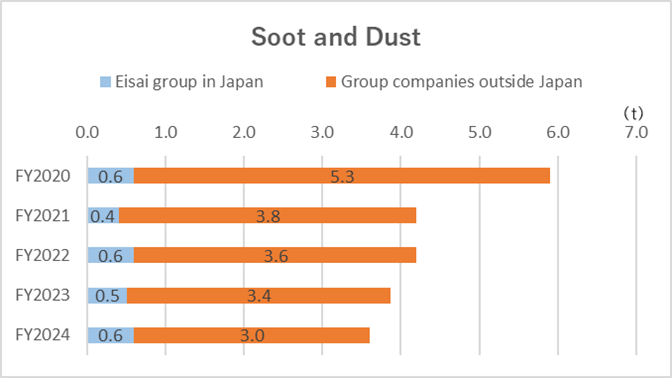

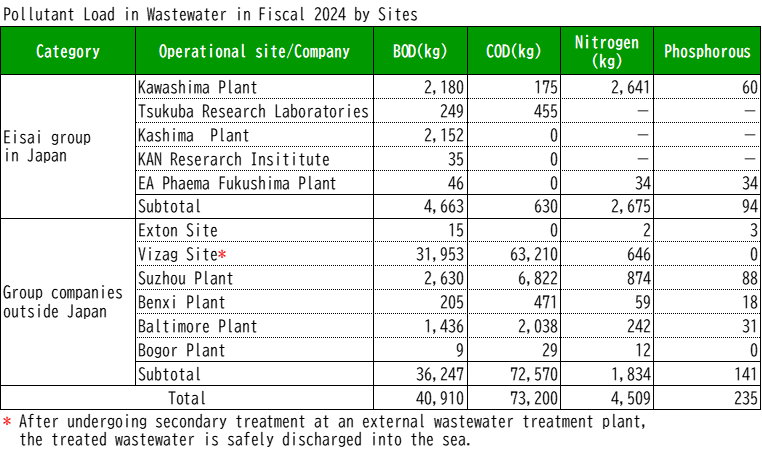

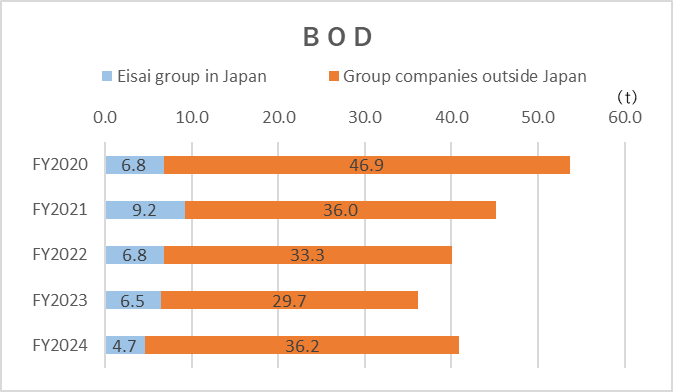

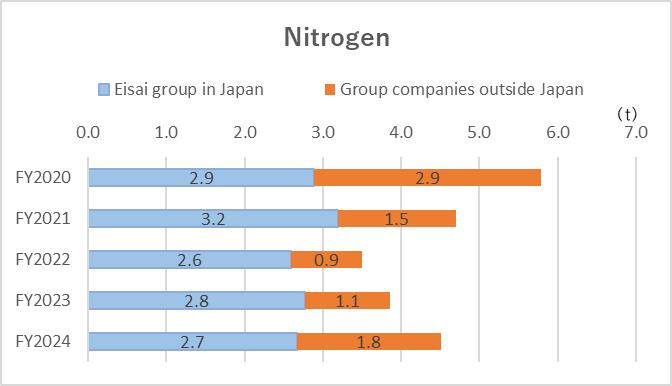

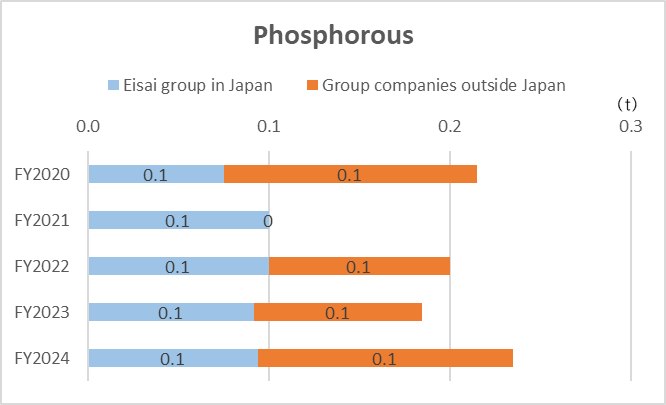

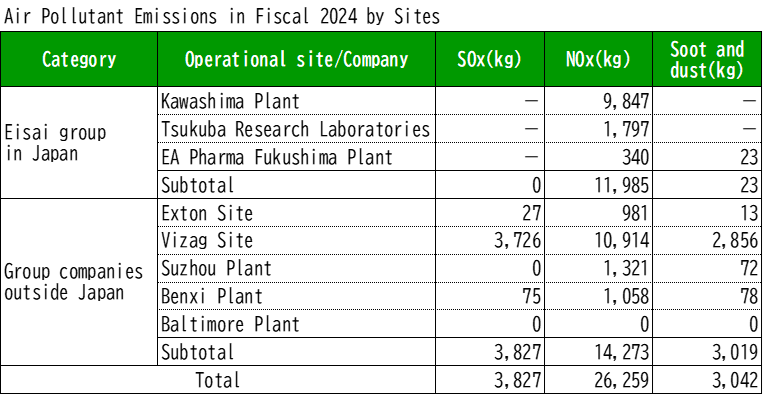

Air Polutant Emissions and Pollutant Load in Wastewater

The Eisai Group strives to comply with environment-related laws, regulations, ordinances, and agreements with local governments, while setting voluntary standards that are stricter than environmental laws and regulations in the course of conducting its business activities. Our plants and laboratories periodically measure their environmental loads that cause air and water pollution to ensure that they are below the standard values. Furthermore, we take countermeasures to prevent leakage of hazardous chemical substances in efforts to not cause pollution of the external environment. We are making continuous efforts to prevent environmental pollution, while conducting regular training regarding response to emergencies.

※ SOx emissions from the Kawashima Plant, Tsukuba Research Laboratories and EA Pharma Fukushima Plant were all below the detection limit. Soot & dust emissions from the Kawashima plant and Tsukuba Research Laboratories were also below detection limit.

“-”indicates values below detection Limit.